การขัดเงาอุปกรณ์ห้องน้ำโลหะผสมทองแดง: เครื่องขัดเงาแบบ Tumbling ให้ได้ผิวกระจกเงา

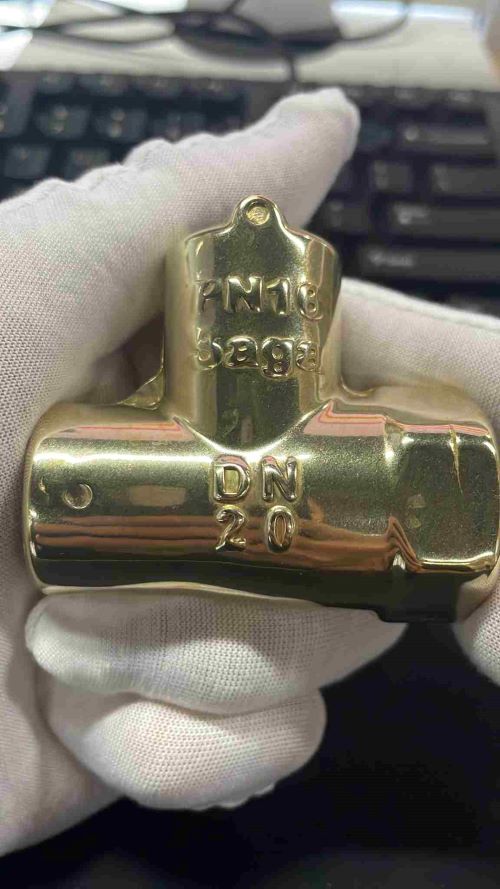

ในโลกแห่งการออกแบบระดับไฮเอนด์ ความน่าดึงดูดใจของ อุปกรณ์ห้องน้ำโลหะผสมทองแดง ปฏิเสธไม่ได้ ความอบอุ่นและความสง่างามของมันสามารถยกระดับพื้นที่ใดๆ ก็ได้ แต่ยังคงไว้ซึ่งความสมบูรณ์แบบและทนทาน การขัดกระจก งานตกแต่งผิวสำเร็จถือเป็นความท้าทายที่สำคัญในการผลิต บทความนี้จะอธิบายว่าเครื่องจักรที่ทันสมัยของเรามอบโซลูชันที่สมบูรณ์แบบได้อย่างไร: การขัดเงาอุปกรณ์ห้องน้ำโลหะผสมทองแดง: เครื่องขัดเงาแบบ Tumbling ให้ได้ผิวกระจกเงา -

ความท้าทาย: พื้นผิวไร้ที่ติบนรูปทรงที่ซับซ้อน

อุปกรณ์ห้องน้ำ เช่น ก๊อกน้ำ มือจับ และฝักบัว ล้วนมีการออกแบบที่ซับซ้อน มีส่วนโค้งและเข้าถึงยาก การขัดเงาด้วยมือแบบดั้งเดิมนั้นต้องใช้แรงงานมาก มีค่าใช้จ่ายสูง และมักส่งผลให้พื้นผิวที่ขัดไม่สม่ำเสมอ เป้าหมายคือการทำให้พื้นผิวมีความเงางามสูงสม่ำเสมอทั่วทั้งพื้นผิว ซึ่งเป็นงานที่เหมาะอย่างยิ่งสำหรับโซลูชันการขัดเงาแบบอัตโนมัติ

โซลูชัน: การตกแต่งด้วยการสั่นสะเทือนประสิทธิภาพสูง

กุญแจสำคัญของการขัดโลหะผสมทองแดงให้บริสุทธิ์อยู่ที่กระบวนการอัตโนมัติที่ควบคุมอย่างแม่นยำ เครื่องขัดผิวแบบกลิ้ง นำเสนอวิธีการที่เหนือกว่าสำหรับการลบคม ขัดผิวให้เรียบ และขัดเงาชิ้นงานจำนวนมากพร้อมกัน กระบวนการขัดผิวด้วยการสั่นสะเทือนนี้ช่วยให้มั่นใจได้ว่าทุกมุมและทุกรูปทรงของอุปกรณ์จะได้รับการขัดเงาอย่างสม่ำเสมอ ส่งผลให้ได้ผิวกระจกคุณภาพสูงที่สม่ำเสมอ ซึ่งวิธีการด้วยมือไม่สามารถเลียนแบบได้

กระบวนการสามขั้นตอนสู่ความสมบูรณ์แบบ

การเคลือบผิวให้เป็นกระจกเป็นกระบวนการหลายขั้นตอนที่ต้องอาศัยการคัดเลือกอุปกรณ์และวัสดุอย่างพิถีพิถัน

- ขั้นตอนที่ 1: การลบคมและการเตรียมพื้นผิว: ขั้นตอนเริ่มต้นใช้สื่อที่มีเกรดหยาบกว่าเพื่อขจัดเสี้ยน รอยแยก หรือจุดบกพร่องบนพื้นผิวจากชิ้นส่วนโลหะผสมทองแดงดิบ เพื่อสร้างฐานที่เรียบเนียนสม่ำเสมอ

- ขั้นตอนที่ 2: การปรับผิวให้เรียบด้วยสารกัดกร่อน: ขั้นตอนต่อไปคือการใช้สารขัดละเอียดขึ้น ขั้นตอนนี้จะช่วยปรับพื้นผิวให้เรียบเนียนยิ่งขึ้น ขจัดรอยขีดข่วนเล็กๆ ที่เหลืออยู่จากขั้นตอนแรก และเตรียมพื้นผิวให้พร้อมสำหรับการขัดเงาขั้นสุดท้าย การเลือก วัสดุขัดถูเป็นสิ่งสำคัญ เพื่อให้ได้ผลลัพธ์ที่ดีที่สุด

- ขั้นตอนที่ 3: การขัดเงากระจก: ขั้นตอนสุดท้ายใช้สารขัดเงาชนิดพิเศษร่วมกับสารขัดเงาชนิดอ่อนที่ไม่กัดกร่อน ส่วนผสมนี้จะช่วยขัดพื้นผิวโลหะผสมทองแดงให้เงางามดุจกระจก

เราได้บันทึกการเปลี่ยนแปลงที่น่าทึ่งโดยใช้วิธีนี้ไว้ หากต้องการดูผลลัพธ์โดยละเอียด โปรดดู กรณีศึกษาการขัดเงาอุปกรณ์ห้องน้ำ -

ยึดมั่นตามมาตรฐานอุตสาหกรรม

การผลิตงานตกแต่งที่มีคุณภาพนั้นไม่ได้ขึ้นอยู่กับความสวยงามเพียงอย่างเดียว แต่ยังรวมถึงความทนทานและประสิทธิภาพด้วย การปฏิบัติตามมาตรฐานอุตสาหกรรมเป็นสิ่งสำคัญอย่างยิ่งยวดเพื่อรับประกันอายุการใช้งานที่ยาวนานและความต้านทานการกัดกร่อน สำหรับข้อมูลเพิ่มเติมเกี่ยวกับข้อกำหนดทางเทคนิค เราขอแนะนำให้ตรวจสอบ ข้อมูลจำเพาะทางเทคนิคสำหรับการขัดโลหะในห้องน้ำ เพื่อทำความเข้าใจมาตรฐานที่ควบคุมการตกแต่งโลหะคุณภาพสูง

พร้อมที่จะทำให้กระจกเงาสมบูรณ์แบบแล้วหรือยัง?

ยกระดับคุณภาพและประสิทธิภาพของสายการผลิตของคุณ สำรวจเครื่องจักรขัดเงาที่ทันสมัยของเราวันนี้

ค้นพบเครื่องจักรของเรา

รองรับเครือข่าย IPv6

รองรับเครือข่าย IPv6